Mofuta oa polasetiki ke sesebelisoa se tsamaisanang le mechini ea ho bopa ea polasetiki indastering ea ho etsa polasetiki ho fa lihlahisoa tsa polasetiki sebopeho se felletseng le boholo bo nepahetseng. Ho latela mekhoa e fapaneng ea ho bopa, e ka aroloa ka mefuta e fapaneng ea hlobo.

1. E phahameng e atolositsoeng polystyrene molding shoa

Ke mofuta oa hlobo o sebelisang polystyrene e ka atolosoang (thepa ea lifaha e entsoeng ka polystyrene le ntho e phophomang) lisebelisoa tse tala ho etsa thepa ea ho paka ea foam ea libopeho tse fapaneng tse lakatsehang.

Molao-motheo ke hore polystyrene e ka atolosoang e ka chesoa ka har'a hlobo, ho kenyelletsa le mefuta e 'meli ea liforomo tse bonolo tsa ts'ebetso le li-hydraulic tse otlolohileng ka polasetiki ea foam, tse sebelisoang haholo ho hlahisa lihlahisoa tsa ho paka lihlahisoa tsa indasteri. Lisebelisoa tsa ho etsa hlobo e joalo ke aluminium e entsoeng ka tšepe, tšepe e sa hloekang, boronse, joalo-joalo.

2. Compress hlobo

Ho kenyeletsoa ho bopa ha compression le ho bopa ente mefuta e 'meli ea hlobo ea sebopeho. Ke mofuta oa hlobo o sebelisoang haholo ho bopa lipolasetiki tsa thermosetting, 'me lisebelisoa tsa bona tse tsamaellanang ke mochini o bopang oa khatiso.

Mokhoa oa ho bōptjoa ha compression Ho ea ka litšoaneleho tsa polasetiki, hlobo e futhumetse mocheso oa mocheso (ka kakaretso 103 ° 108 °), ebe phofo ea compression e lekantsoeng e kenngoa ka sekoting sa hlobo le kamoreng ea ho fepa, hlobo e koetsoe, 'me polasetiki e futhumetse tlas'a mocheso o phahameng le khatello e phahameng. Nolofatsa phallo ea viscous, tiisa le sebopeho ka mor'a nako e itseng, 'me e be sebopeho sa sehlahisoa se lakatsehang.

Phapang pakeng tsa ho bopa ka ente le ho bopa ha khatello ke hore ha ho na kamore ea ho fepa e arohaneng. Hlobo e koetsoe pele e bōptjoa, 'me polasetiki e chesoa pele ka kamoreng ea ho fepa' me e fetoha boemo ba phallo ea viscous. Tlas'a ketso ea khatello, e fetoloa 'me e petelitsoe ka har'a sekoti sa hlobo ho thatafatsa le ho theha.

The compression hlobo haholo-holo e entsoe ka cavity, ho fepa cavity, mochine o tataisang, likarolo tsa ejecting, tsamaiso ea ho futhumatsa, joalo-joalo. Lisebelisoa tse sebelisoang ha ho etsoa liforomo tsa compression ha e le hantle li tšoana le hlobo ea ente.

3. Ente hlobo

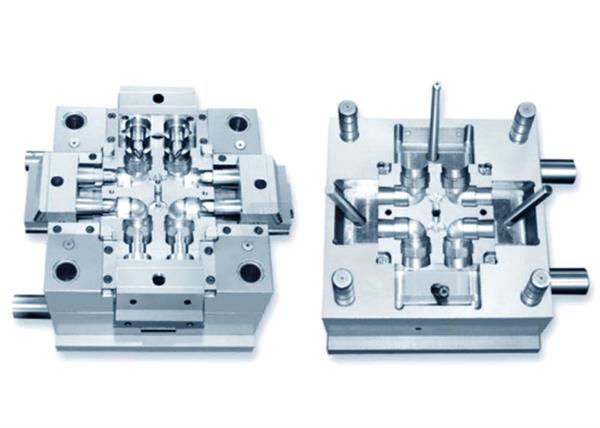

Haholo-holo ke hlobo e bōpiloeng e sebelisoang haholo ha ho etsoa likarolo tsa thermoplastic. Thepa ea ts'ebetso e tsamaellanang le hlobo ea ente ke mochini oa ente. Polasetiki e qala ho futhumatsoa ebe e qhibiliha ka har'a moqomo o futhumatsang o ka tlase ho mochini oa ho bopa ente. Tlas'a ho sutumetsa polaka, e kena ka sekoting sa hlobo ka mochini oa mochini oa ente le tsamaiso ea ho tšela hlobo, 'me polasetiki e pholile ebe e thatafalloa ho theha,' me sehlahisoa se fumanoa ka ho bopa.

Sebopeho sa eona hangata se entsoe ka likarolo tsa ho etsa likarolo, tsamaiso ea ho tšela, likarolo tse tataisang, mochine oa ho sutumetsa, tsamaiso ea taolo ea mocheso, tsamaiso ea ho qeta, likarolo tse tšehetsang le likarolo tse ling, 'me e entsoe ka tšepe ea hlobo ea polasetiki. Mokhoa oa ho etsa ente hangata o loketse feela tlhahiso ea lihlahisoa tsa thermoplastic. Lihlahisoa tsa polasetiki tse hlahisoang ke mokhoa oa ho bopa ente li pharaletse haholo. Ho tloha ho litlhoko tsa letsatsi le letsatsi ho ea ho lisebelisoa tse fapaneng tse rarahaneng tsa motlakase le likarolo tsa koloi, kaofela li entsoe ka hlobo ea ente. E 'ngoe ea mekhoa e sebelisoang ka ho fetisisa ea ho sebetsa ha ho etsoa lihlahisoa tsa polasetiki.

4. Foka hlobo

Hlobo e sebelisetsoang ho etsa lihlahisoa tse se nang letho tsa polasetiki (joalo ka libotlolo tsa seno, lihlahisoa tsa letsatsi le letsatsi tsa lik'hemik'hale le lijana tse ling tsa ho paka). Sebopeho sa ho phunya ho kenyelletsa haholo-holo ho kopanyelletsa ho bopa ha extrusion le molding ea ente ho latela molao-motheo oa ts'ebetso. Molao-motheo ona haholo-holo o akarelletsa extrusion blow molding, ente blow blowing, ente katoloso letsa molding (hangata e tsejoa e le ente otlolla kotlo), multi-lara blow molding, sheet blow molding, joalo-joalo Thepa e tsamaellanang le ho bōptjoa ha sekoti sa lihlahisoa tse sekoti hangata ho bitsoa polasetiki. mochini oa ho bopa o otlang, 'me ho bopa ho foka ho loketse feela tlhahiso ea lihlahisoa tsa thermoplastic. Sebopeho sa hlobo ea ho otla se batla se le bonolo, 'me lisebelisoa tse sebelisoang hangata li entsoe ka carbon.

5. Extrusion shoa

Mofuta oa hlobo o sebelisetsoang ho hlahisa lihlahisoa tsa polasetiki tse bōpehileng ka mokhoa o tsoelang pele, o tsejoang hape e le hlooho ea extrusion molding, o sebelisoa haholo ha ho etsoa liphaephe, mekoallo, li-monofilaments, lipoleiti, lifilimi, terata le li-cable cladding, lisebelisoa tsa profiled, joalo-joalo.

Thepa e lumellanang ea tlhahiso ke extruder ea polasetiki. Molao-motheo ke hore polasetiki e tiileng e qhibilihisoa 'me e entsoe ka polasetiki tlas'a maemo a ho futhumatsa le "screw rotation" ea extruder,' me e entsoe ka karolo e tšoanang ea sefapano e le sebōpeho sa lefu ka ho shoa ha sebopeho se itseng. Lihlahisoa tsa polasetiki tse tsoelang pele. Lisebelisoa tsa eona tsa tlhahiso haholo-holo ke tšepe e entsoeng ka carbon, lisebelisoa tsa alloy, joalo-joalo, 'me li-extrusion dies li boetse li khabisitsoe ka thepa e sa senyeheng e kang daemane likarolong tse hlokang ho khathala.

Ts'ebetso ea extrusion hangata e loketse feela tlhahiso ea lihlahisoa tsa thermoplastic, tse fapaneng haholo le hlobo ea ente le hlobo ea compression ka sebopeho.

6. Mofuta oa blister

Hlobo e sebelisang lipoleiti tsa polasetiki le maqephe e le lisebelisoa tse tala ho etsa lihlahisoa tse bonolo tsa polasetiki. Tabeng ea ho nolofatsa, e holofetse 'me e khomaretsoe ka sekoting sa hlobo ho fumana sehlahisoa se bōpiloeng se lakatsehang, se sebelisoang haholo ho hlahisa litlhoko tse ling tsa letsatsi le letsatsi, lijo le lihlahisoa tsa ho paka lintho tsa ho bapala.

Nako ea poso: Feb-12-2022